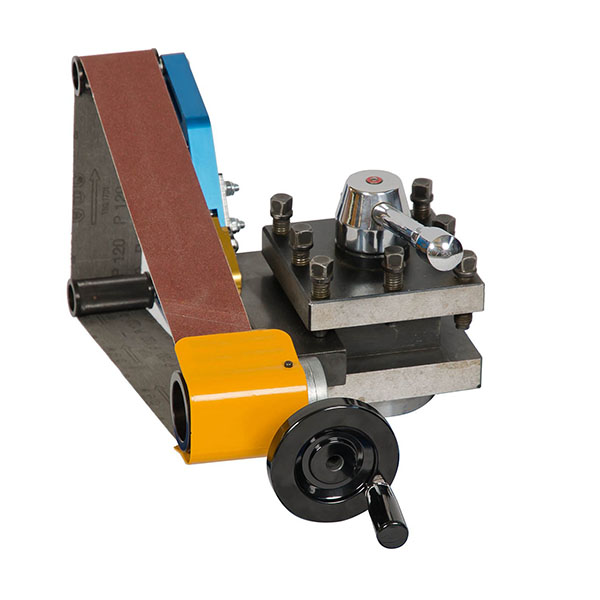

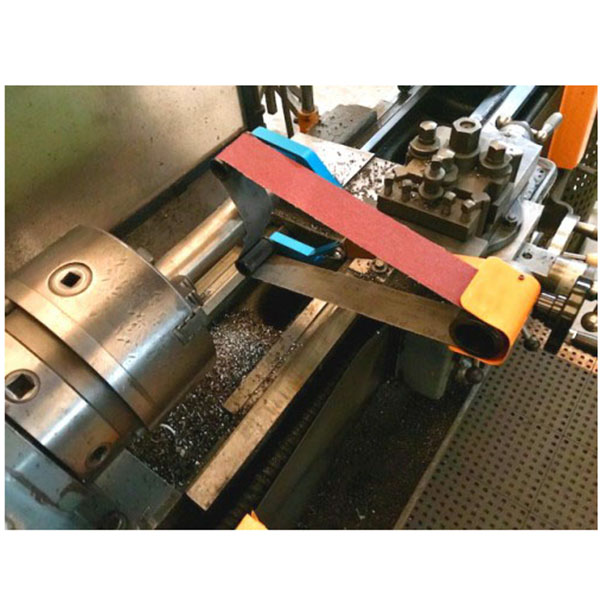

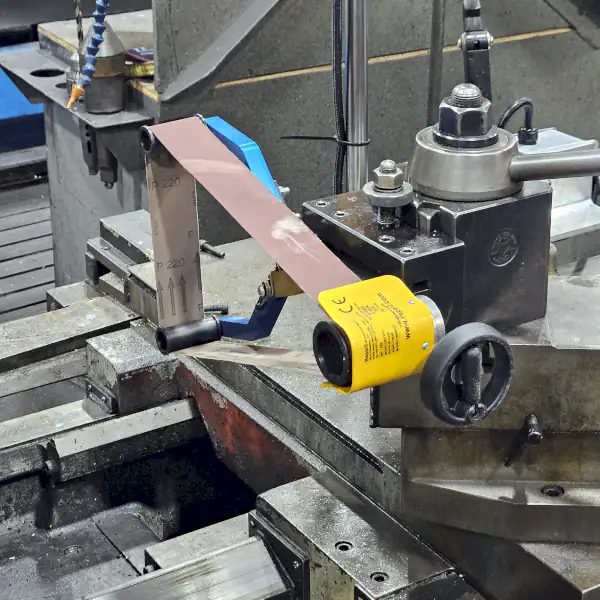

This lathe tool-post-belt-sanding attachment is much safer than using abrasive cloth/paper on lathes. The belt sander attachment fits right into your existing toolpost. Use it to polish or deburr parts.

Lathe Tool Post Belt Sander Attachment Features

- Automatically adjusts to the diameter of your workpiece.

- Supplied with three belts (80, 120, and 220 Grit)

- Quick attachment to the lathe toolpost.

Use this safety accessory with our model TC chip shield for lathes.

Lathe Sanding Attachment Models Available

Using Emery Cloth on Lathes

Emery cloth or abrasive cloth paper has traditionally been used on conventional lathes to achieve the required tolerances in precision work. The fabric’s abrasive surface polishes or deburrs cylindrical metal parts. This belt sander attachment removes the need to use abrasive cloth or paper on a conventional lathe.

The Hazard

Using emery cloth and sandpaper on metalworking lathes results in many accidents. A strip of emery cloth is held between both hands and wrapped around the backside of the rotating workpiece. If the fabric becomes snagged on the workpiece and wrapped around the fingers on the other end, the risk of injury is high. Injuries include broken bones, lacerations, and even amputations.