Ferndale Safety Engineering Projects

Remote Control of a VTL

A large aerospace manufacturer tasked Ferndale Safety with engineering and integrating a remote control system for a vertical turret lathe (VTL). This was done after we fully enclosed the chuck with guarding, preventing the operator from reaching a critical handwheel.

Electrical Engineering Meets Safety

A large safety guard installed by Ferndale Safety around a vertical turret lathe (VTL) made an important machine handwheel inaccessible. Ferndale Safety’s team of mechanical and electrical engineers replaced the handwheel with a remote control that could make fine to coarse adjustments.

What is a vertical lathe?

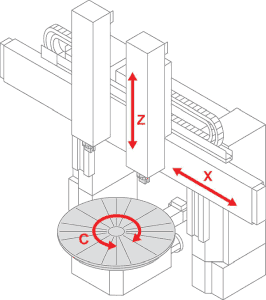

A vertical lathe works like a standard lathe, turned on its side. It can also be called a vertical turning lathe or vertical turret lathe (VTL).

Ferndale Safety was tasked with installing a safety guard around a vertical turret lathe. It was clear that the machine’s handwheel would no longer be accessible after the safety guard was installed. One of the challenges that Ferndale Safety’s engineering team had was the handwheel location. The handwheel would move with the column and turret – and would never be in the same position at any given time. Ferndale Safety suggested to the client that the best solution was to design a remote control system custom-designed for this machine’s handwheel. The client loved the idea and had Ferndale Safety design and implement the remote control system.

Remote Control Pendant

Ferndale Safety used as many off-the-shelf components as this control pendant to reduce final costs. The remote control includes an enabling button to prevent accidental movement and a speed adjustment for fine or coarse adjustments.

The Manual Handwheel

The manual handwheel had a scale on the side to allow for precise movements of the handwheel. The handwheel is used for manual movements of the machine during the setup process.

The Remote Handwheel

The electrical version of the manual handwheel used a motor and timing belt system to allow for precise movements. This was controlled with a remote control pendant.