Ferndale Safety Engineering Projects

Custom-Made Safeguarding for a Small Lathe

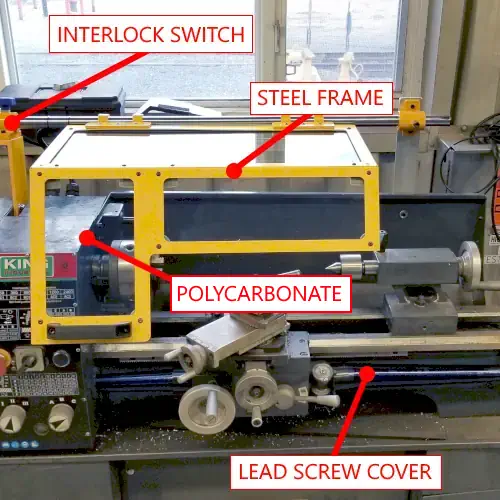

A private railway commissioned Ferndale Safety to safeguard a small King Industrial lathe.

Project Requirements

- Cover the whole bed area, including the chuck, toolpost, cross slide, and the part to be machined.

- Cover the rotating lead screw.

- Include a safety interlock that disables the machine when the guard is open.

- Allow lots of light to enter for visibility.

- Easy to maintain and clean.

Lathe Safeguarding Features

Flip-Open Design for Maximum Accessibility

Do you have a safeguarding project?

Ferndale Safety can help you with:

Please fill out the form below so that one of our safety experts can call you. Alternatively, you can click here to send us a message.